Built-In Toolchains for Fast, Scalable Inspection

Fast Deployment. Scale with Ease.

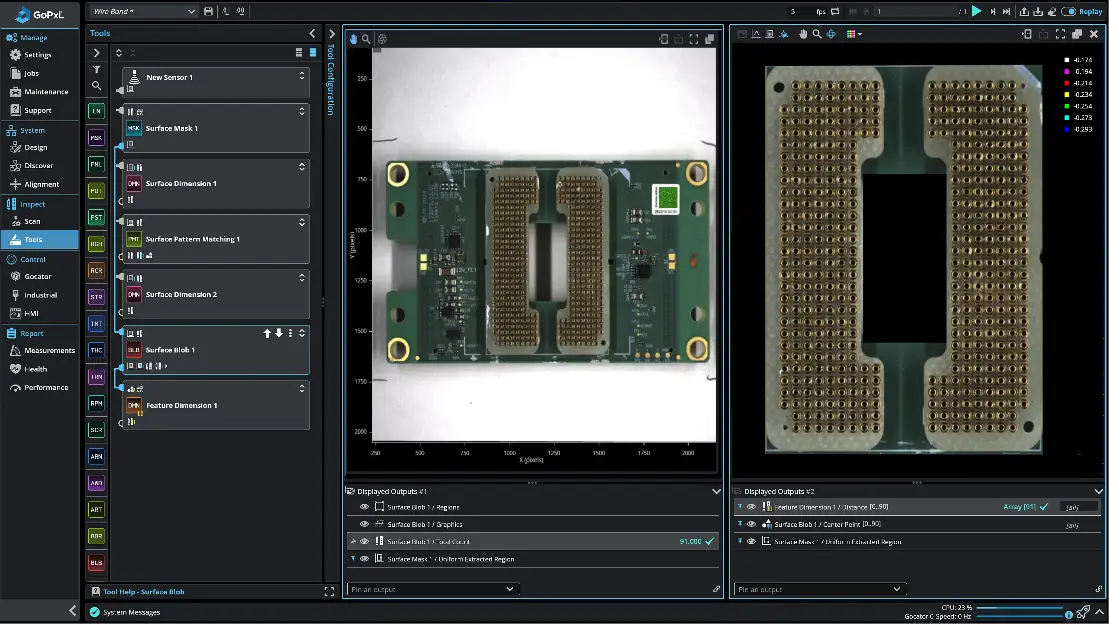

Gocator® 2D Smart Cameras are powered by GoPxL, a browser-based software platform with a full suite of built-in vision workflows comprised of pre-configured toolchains that require no coding or external software. Simply connect, configure, and run your inspections directly on the camera. Whether you’re aligning parts, measuring gaps, detecting defects, or reading barcodes, Gocator gives you the ability to build complete inspection pipelines with ease, and scale them across your line with no added complexity.

Smart Vision Workflows

Achieve sub-pixel accuracy for locating and orienting parts in high-speed applications.

Tools:

Edge & Corner Detection, Pattern Matching, AI Locate

Use Cases:

• Part alignment and orientation

• Measuring gaps, diameters, and offsets

Count, filter, and validate object consistency with pixel-level control.

Tools:

Blob Detection, Area Filters, Intensity Thresholding

Use Cases:

• Presence verification of features or parts

• Contamination or flaw detection in defined zones

Detect surface defects—trained or untrained—without the need for labeled datasets.

Tools:

AI Anomaly Detector, Contrast-Based Sensing, Multi-Zone Analysis

Use Cases:

• Flaw or defect detection in complex textures

• Surface inspection in unpredictable environments

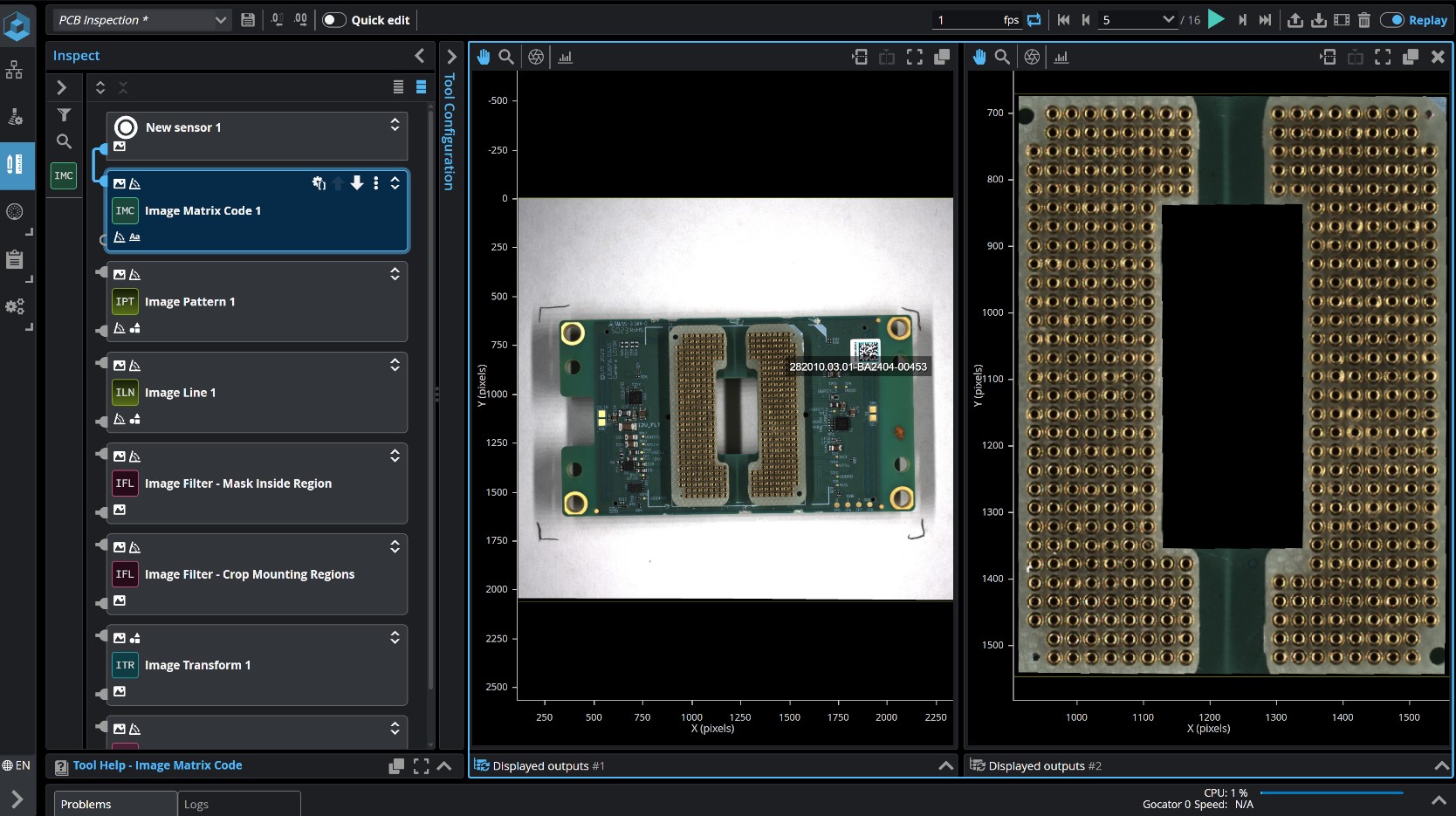

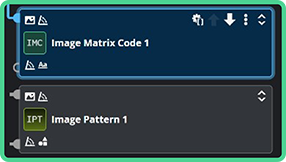

Decode printed or etched codes for full traceability across the production line.

Tools:

Barcode Reader, Data Matrix Grading, OCR

Use Cases:

• Serial number reading

• Product tracking and compliance verification

Validate presence, shape, and uniformity using region-based logic.

Tools:

Pixel Counting, Mask Overlays, Feature Detection

Use Cases:

• Verifying part presence or position

• Confirming consistent fill or coverage

Optimize image clarity and signal quality before analysis.

Tools:

Gaussian & Median Filters, Math Operations, Adaptive Thresholding

Use Cases:

• Enhancing edge clarity for measurement

• Filtering noise to improve defect detection

Example Inspection Pipelines

Feature Measurement (in Millimeters)

Align Using Edge Tool

Track Part with Pattern Matching

Measure Distance Between Edges

Fast, repeatable measurement in millimeters with no post-processing.

Part Location and Opening Radius Measurement

Track Part Using Pattern Matching

Locate Opening with Circle Tool

Measure Inner Radius

Reliable real-world measurement of part openings, even with partial visibility.

Gasket Width Measurement

Track Gasket Using Pattern Matching

Measure Width with Track Tool

Pattern-based gasket inspection with accurate, repeatable measurement using just two tools.

Chip Bag Classification

Collect Images of Different Part Classes

Train On-Camera Classification Model

Classify Each Frame with Confidence Scoring

On-camera part classification for up to 10 classes, optimized for challenging conditions.

No-Code Simplicity. Pro-Level Power.

Gocator 2D cameras solve real factory challenges—fast. From detecting defects to verifying barcodes and measuring features, they deliver accurate results at production speeds. Easily integrated into electronics, automotive, and packaging lines, Gocator 2D is your go-to for smart, scalable inspection.

GoPxL Python GDK — Full Custom Control

For power users and advanced developers, the GoPxL Python GDK lets you create fully customized measurement tools and inspection workflows. Deploy directly on Gocator 2D Smart Cameras, GoMax, or a PC, and integrate seamlessly with AI frameworks like PyTorch and TensorFlow.

- Write custom logic in Python for unique inspection needs

- Combine open-source AI models with GoPxL workflows

- Deploy on-camera or edge devices for low-latency, high-throughput inspection

The Python GDK gives you complete control over your vision solution — from rapid prototyping to full-scale production, without compromise.