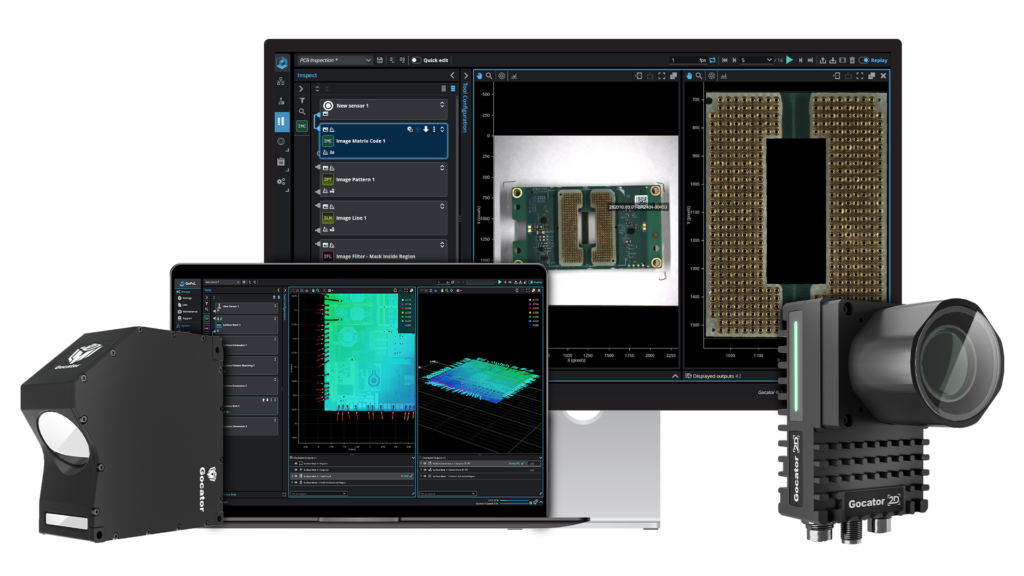

The Gocator Ecosystem: One Platform.

Unified 2D + 3D Vision. Edge-Native Intelligence.

Run synchronized 2D and 3D inspection on a single, integrated smart vision platform.

Powered by GoPxL and GoMax.

The Gocator Ecosystem brings together Smart 2D Cameras, Smart 3D Sensors, and GoMax edge accelerators into one seamless vision platform, built for real-world inspection at the edge. From surface defects to dimensional measurement, you can deploy 2D and 3D tools side-by-side, on the same line, without middleware, PCs, or cloud dependencies.

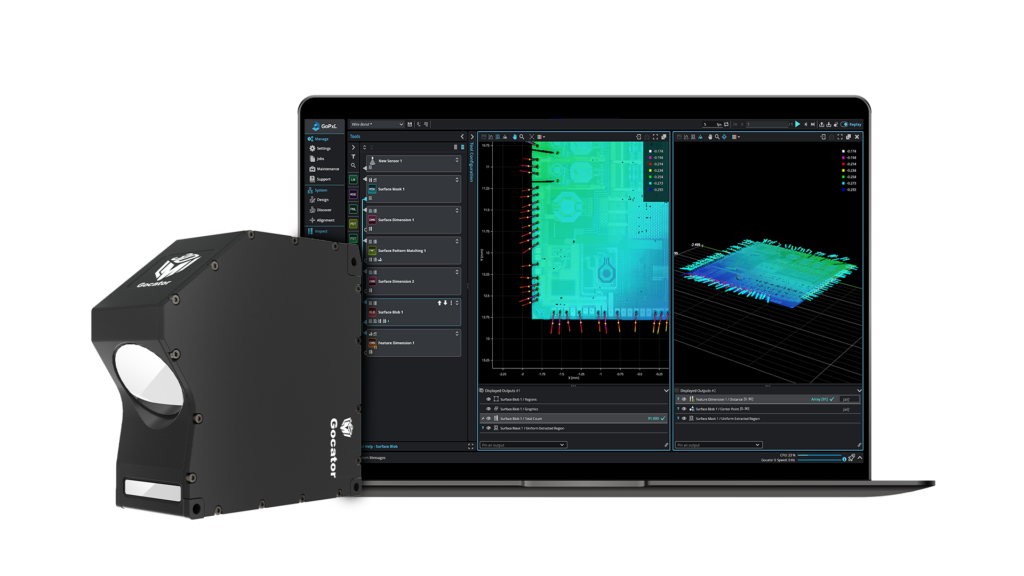

At the heart of it all is GoPxL, a powerful, browser-based software environment that runs directly on every Gocator device or on a GoMax edge device. Whether you’re setting up a ring inspection using 2D AI or checking pin height with 3D laser profiling, everything works in perfect sync with a single job file, one user interface, and zero vendor lock-in.

How a Gocator 2D+3D System Works

2D + 3D Integration Made Simple

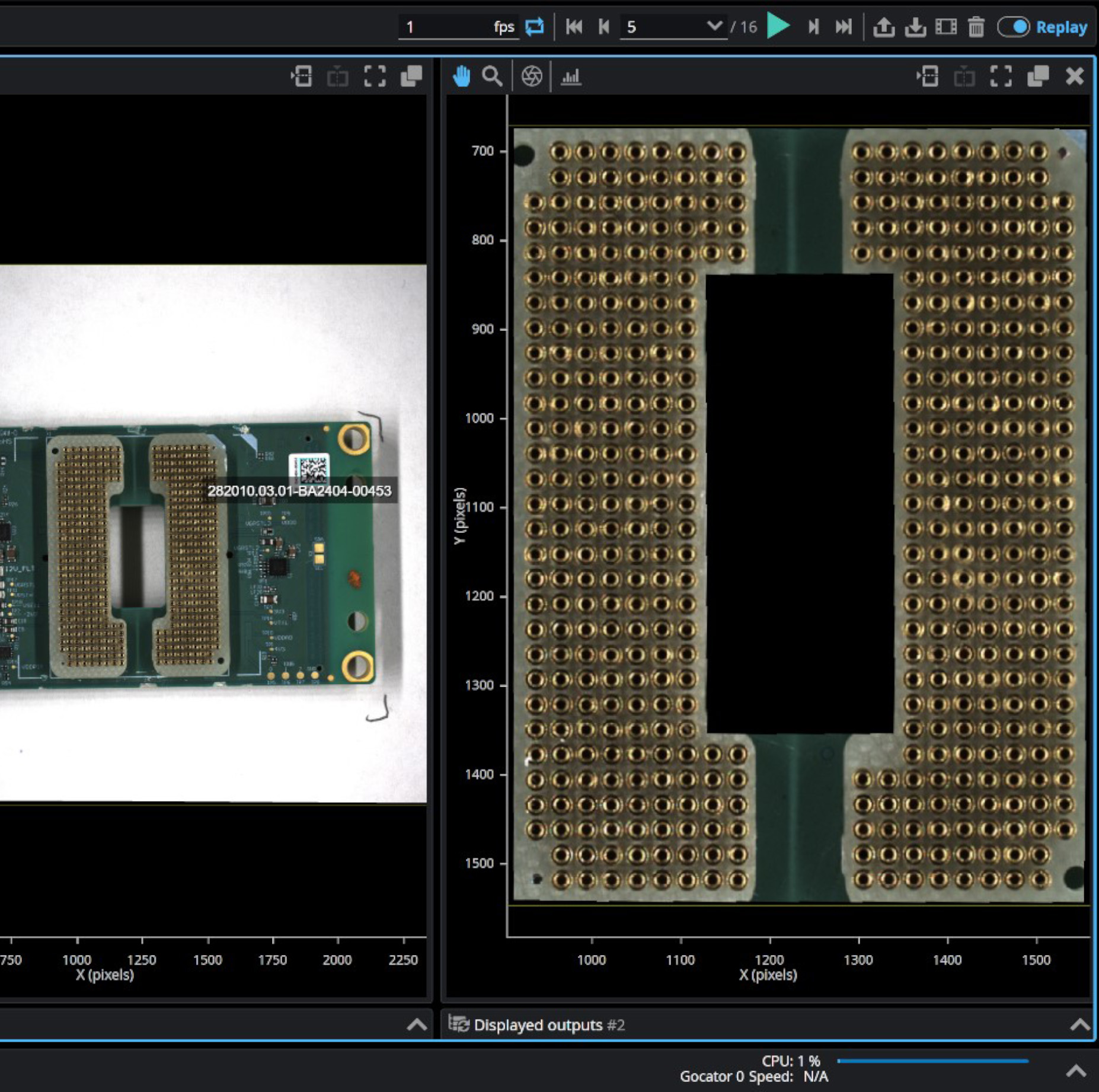

Gocator 2D Smart Cameras

perform high-speed surface, edge, or OCR inspections using onboard AI and traditional tools.

Gocator 3D Smart Sensors

deliver high-resolution height and shape measurements using laser line, line confocal, or structured light technologies.

GoPxL Software

runs on both devices, allowing you to configure, combine, and deploy synchronized inspection pipelines across devices—browser-based, no PC required.

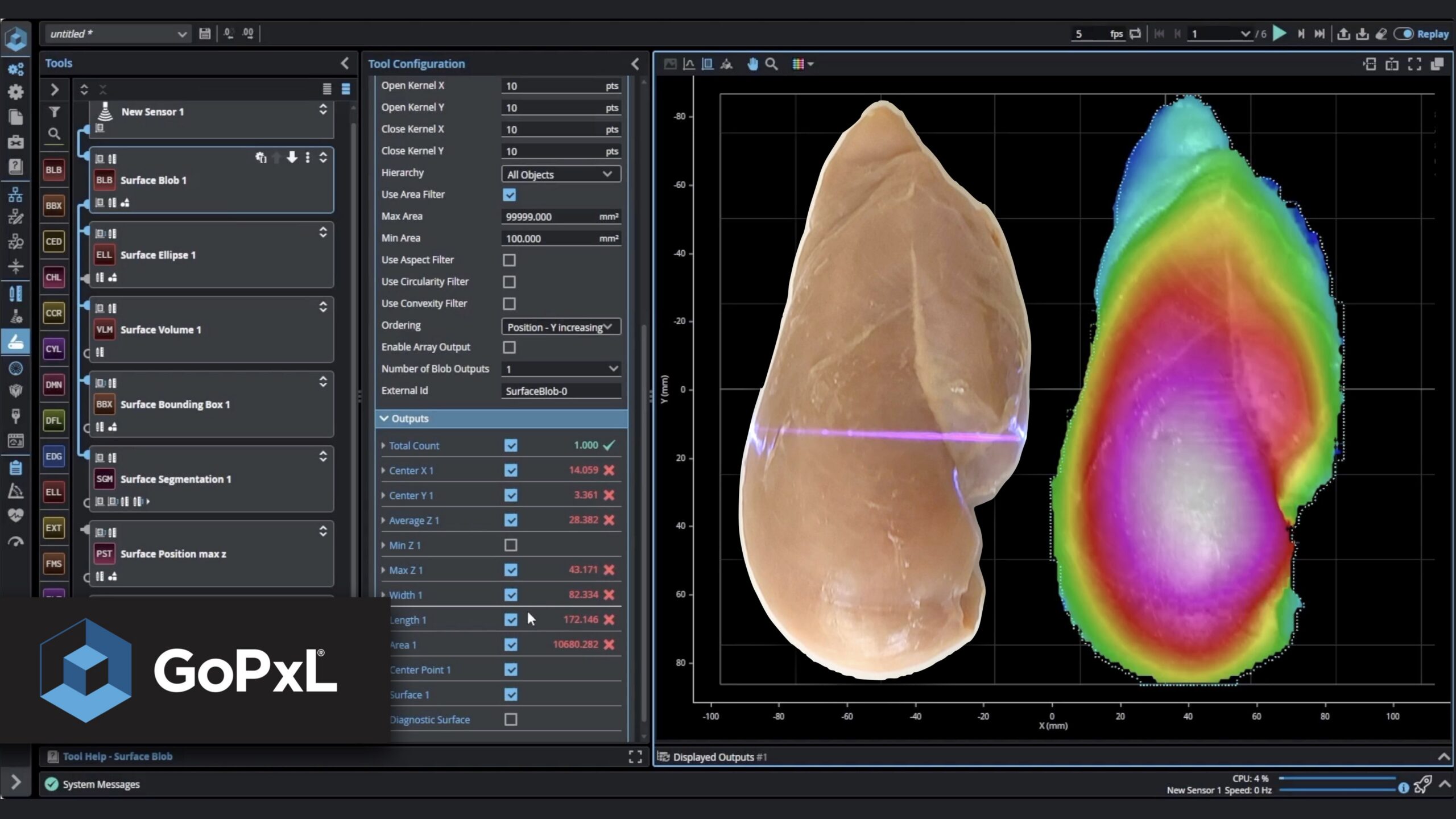

Example: Chicken Breast Inspection

Benefits of a Unified Gocator Ecosystem

One Platform. Total Control.

Software

Deployment

Integration Effort

Scalability

Hardware Architecture

Support & Maintenance

Gocator Ecosystem

Single platform (GoPxL) for 2D + 3D

Browser-based, on-device

Native, synchronized inspection

Add devices, copy job files

All-in-one smart sensors

Unified toolchain, single vendor

Traditional Mixed 2D/3D Systems

Multiple UIs and SDKs

PC-based IDEs or cloud dependencies

Manual alignment and triggering

Reconfigure pipelines, revalidate

Fragmented sensors, PCs, enclosures

Multiple vendors, compatibility risks

Why It Matters

Most machine vision systems force manufacturers to cobble together 2D and 3D components from different vendors—each with their own software, setup, and support. The result? Longer development cycles, higher maintenance overhead, and unpredictable runtime behavior.

Gocator eliminates that complexity with a unified vision platform where everything is designed to work together—hardware, software, and AI tools included. That means faster deployment, more reliable performance, and a dramatically lower total cost of ownership.

Faster Time to Value

2D + 3D inspections deployed in hours, not weeks

Lower Integration Overhead

No middleware, no sync issues, no custom code

Flexible Deployment

Mix and match Smart Cameras and Sensors across lines

Future-Proof Architecture

One software platform that evolves with your factory

Edge-Native Processing

AI + traditional tools run directly on every device

Unified Support

One partner, one platform, one roadmap